Rayyu cares about the quality of the tools, which is to deliver strict standards and near-perfect products for your brand

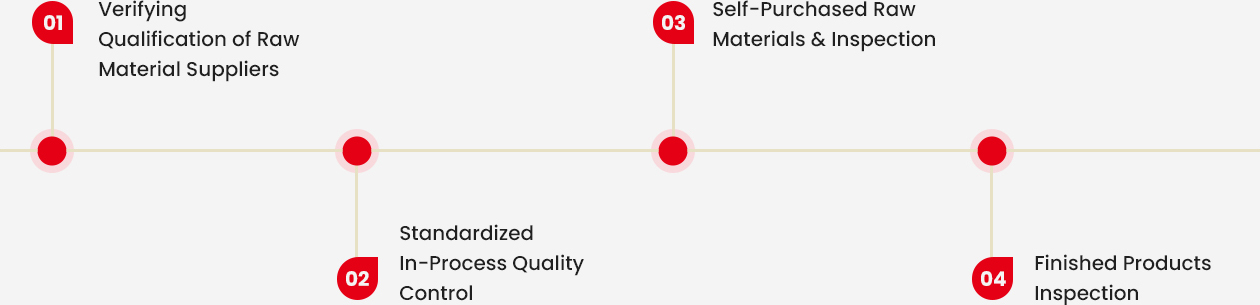

Supply chain raw material inspection-IQC

Rayyu control the purchase of raw materials, make quality confirmation, reduce the quality of the resulting cost increases, and achieve effective control of material quality.

Production Process Flow Implementation Standard - SOP

During the production process, workers operate the equipment according to the customized standard process steps and comply with the production product precautions.

Production process quality control - IPQC

During the production process, regularly check and confirm the changes of production process parameters, and record the testing status to control and supervise as necessary.

Final quality inspection - FQC

Rayyu completes all the production and process of the manufactured products and conducts step-by-step quality inspection.

Finished product sampling inspection - AQL

Rayyu has strict standards for your branded products, and samples are tested before final delivery to ensure we lead high quality products for you.